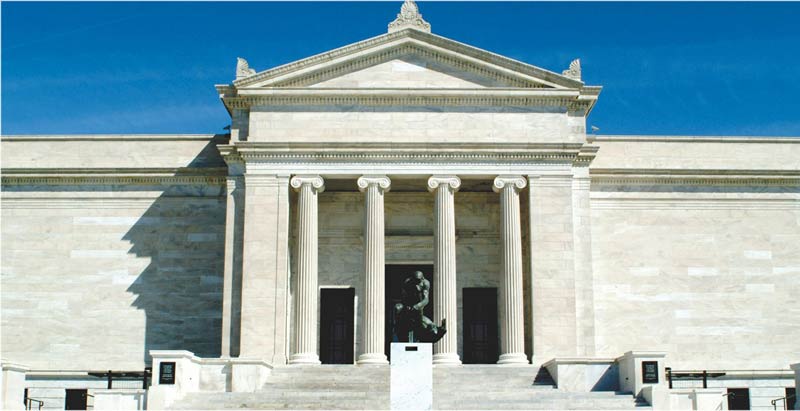

Historic Masonry

Graciano is one of the country’s best-known historic masonry restoration firms. We have extended the lifespan of hundreds of historic structures, allowing numerous organizations to continue using their architecturally significant buildings.

Graciano Corporation is experienced in all facets of historic restoration – from structural stabilization to aesthetic rehabilitation – and maintains one of the largest and most skilled historic restoration workforces in the industry. We are frequently recognized by building owners and preservation organizations for the excellence of our craftsmanship and our adherence to the strict Historic Landmark guidelines that govern historic restoration projects.

Historic Masonry Services Offered

Over time, moisture, pollution and exposure to the elements can compromise the structural integrity and appearance of a building. In addition, as some building materials age, they tend to become brittle, susceptible to cracking, spalling or oxidation, or prone to disintegration. Alone or in combination, these factors may ultimately threaten the structural stability and usefulness of the building. Graciano offers a complete range of historic masonry restoration services that renew the appearance of buildings and protect them from further deterioration.

- Waterproofing It’s important to waterproof concrete structures to keep moisture out of the facility and to protect the structural components of concrete and imbedded reinforcing steel. If the integrity of the concrete is maintained, it can remain waterproof. Polyurethane is considered one of the best waterproofing materials. It can be applied seamlessly and penetrates the surface deeply and evenly. The polyurethane membrane will fill in even the finest cracks in concrete, reducing its water absorbency capacity. Many types of waterproofing systems can be used depending on your home’s structure

- Urethane Foam or Epoxy Injection Urethane Foam or epoxy injection is a cost-effective and permanent way to stabilize and seal cracked or compromised masonry surfaces. Depending on the size of the crack, urethane foam or epoxy is injected into the void and allowed to cure. Once hardened, these materials help form a stable subsurface to support masonry restoration operations.

- Tuck Pointing Tuck pointing entails removing loose or cracked mortar from brickwork or stone installations and replacing its new mortar to ensure structural integrity and to seal out damaging water and moisture. Mortar for tuck pointing must be carefully selected to ensure that its color and texture of the new mortar closely matches the existing material that was not compromised and did not need to be removed.

- Terra Cotta Replacement and Repair Terra cotta is a building material that is cast from clay and then glazed. Terra cotta components add great color and detail to a building, but are also highly susceptible to cracking and damage from impacts or freeze and thaw cycles. In many cases, damaged terra cotta sections must be removed and replaced with new materials to prevent water infiltration and structural damage. Replacement components must be created to replicate the design of the original piece, as well as the coloration that is acquired as the surrounding pieces age. Frequently, it is necessary to repair and stabilize the structural underpinnings that support a terra cotta installation, as corroded pins or structural supports can cause further damage as time passes. In cases where a terra cotta component has sustained minor damage, it is often possible to perform repairs on the piece without removing the compromised element from its installation.

- Masonry Cleaning Masonry cleaning entails the removal of dirt, debris, paint, and graffiti from various surfaces of masonry structures. Commonly used masonry cleaning techniques include high and low – pressure washing and chemical cleaning. Regardless of the method used, special care is taken to avoid over cleaning – and possibly damaging – aging masonry surfaces.

- Caulking Caulking is used to seal gaps between masonry surfaces, such as brick or stone, and other architectural elements, including window and door frames, decorative hardware or lighting fixtures. Caulking is most often applied with a gun, and is available in butyl, latex or customized formulations. The color of caulk is selected to match the surfaces surrounding the application site. When applied, the caulking gun is inserted in the gap to be filled. Caulking material is then injected into the void to seal the opening.

- Abrasive Cleaning Heavily soiled masonry surfaces may require abrasive cleaning to effectively remove deposits of grime, paint or graffiti. Abrasive cleaning typically involves high–pressure application of sand or another type of inert, abrasive material directly to the masonry surface. When the abrasive cleaning has been completed, the masonry surface is frequently rinsed with low-pressure water to remove any remaining dirt or cleaning materials.

Contact