Masonry Restoration

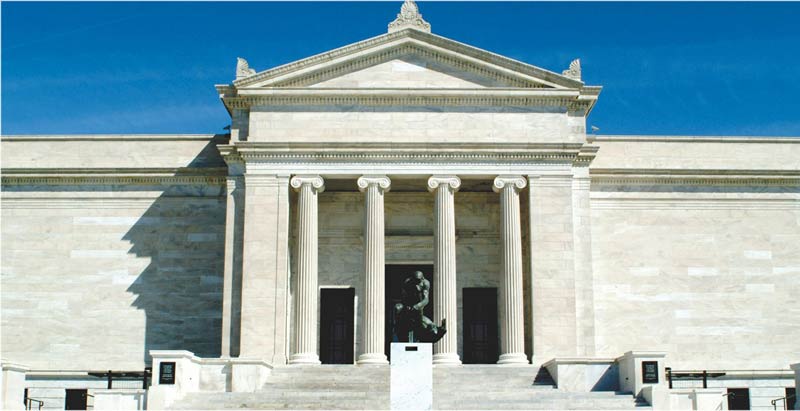

Graciano Corporation is a leader in masonry restoration, both interior and exterior. We maintain one of the most skilled workforces in the industry, and many of our journeymen are third-generation professionals.

Masonry restoration can significantly extend the useful life of historic landmarks, as well as business, public, industrial and municipal buildings. Graciano continues to be recognized for the excellence of our craftsmanship and the depth of our technical expertise by industry organizations and leading historic preservation organizations alike.

Graciano Corporation serves clients throughout the United States, and is bonded, licensed and insured in all states of operation. We maintain a comprehensive safety program in compliance with OSHA and MSHA Standards, and we are licensed to apply numerous state-of-the-art finishes, grouts and sealants.

Masonry restoration projects include Rockefeller Center, MetLife Building Brooklyn Academy of Music and Belvedere Castle.

Masonry Restoration Services Offered

Moisture, pollution and exposure to the elements can all compromise the appearance of a building. They may also threaten structural stability, and ultimately hinder the usefulness of the structure. Graciano offers a complete range of masonry restoration services that renew the appearance of brick and stone surfaces and protect them from further deterioration.

- Waterproofing It’s important to waterproof concrete structures to keep moisture out of the facility and to protect the structural components of concrete and imbedded reinforcing steel. If the integrity of the concrete is maintained, it can remain waterproof. Polyurethane is considered one of the best waterproofing materials. It can be applied seamlessly and penetrates the surface deeply and evenly. The polyurethane membrane will fill in even the finest cracks in concrete, reducing its water absorbency capacity. Many types of waterproofing systems can be used depending on your home’s structure

- Urethane Foam or Epoxy Injection Urethane Foam or epoxy injection is a cost-effective and permanent way to stabilize and seal cracked or compromised masonry surfaces. Depending on the size of the crack, urethane foam or epoxy is injected into the void and allowed to cure. Once hardened, these materials help form a stable subsurface to support masonry restoration operations.

- Tuck Pointing Tuck pointing entails removing loose or cracked mortar from brickwork or stone installations and replacing its new mortar to ensure structural integrity and to seal out damaging water and moisture. Mortar for tuck pointing must be carefully selected to ensure that its color and texture of the new mortar closely matches the existing material that was not compromised and did not need to be removed.

- Masonry Cleaning Masonry cleaning entails the removal of dirt, debris, paint, and graffiti from various surfaces of masonry structures. Commonly used masonry cleaning techniques include high and low – pressure washing and chemical cleaning. Regardless of the method used, special care is taken to avoid over cleaning – and possibly damaging – aging masonry surfaces.

- Grouting Grouting is used to seal the spaces between masonry installations such as tile or terra cotta. Grout may be colored to blend with the masonry materials, or can be used to create contrast within the masonry design. Grout is typically applied by hand by filling the joints with material and then troweling it out over the adjoining tile or terra cotta. Once the grout has set, a craftsman returns to the area that was grouted and removes any excess material from the face of the installation. As grout is frequently porous, it must be sealed once it is completely dry to protect it from dirt infiltration.

- EIFS Cleaning Exterior Insulation and Finish Systems cleaning, also known as EIFS cleaning, involves removing dirt and grime from the exterior surfaces of structures clad in Dryvit or other types of stucco–like materials. To avoid damaging the thin exterior skin of these structures, mild cleaning agents and low–pressure water is most frequently used to dislodge surface dirt. Manual cleaning is also used to remove dirt in hard–to–reach areas or intricate detail.

- Caulking Caulking is used to seal gaps between masonry surfaces, such as brick or stone, and other architectural elements, including window and door frames, decorative hardware or lighting fixtures. Caulking is most often applied with a gun, and is available in butyl, latex or customized formulations. The color of caulk is selected to match the surfaces surrounding the application site. When applied, the caulking gun is inserted in the gap to be filled. Caulking material is then injected into the void to seal the opening.

- Abrasive Cleaning Heavily soiled masonry surfaces may require abrasive cleaning to effectively remove deposits of grime, paint or graffiti. Abrasive cleaning typically involves high–pressure application of sand or another type of inert, abrasive material directly to the masonry surface. When the abrasive cleaning has been completed, the masonry surface is frequently rinsed with low-pressure water to remove any remaining dirt or cleaning materials.

Contact