Chester Engineers’ Project Engineer, Mark Mellott said, “We were all very impressed with Graciano’s work. They filled all the voids so the integrity of the surface would not compromise the liner and I believe it was the fastest expedition of a project I have ever seen.”

Graciano Corporation, a recognized leader with over 80 years of structural concrete, masonry and terra cotta restoration and repair experience, was selected as the Restoration Team for the Lanphor Reservoir located in Pittsburgh, Pennsylvania.

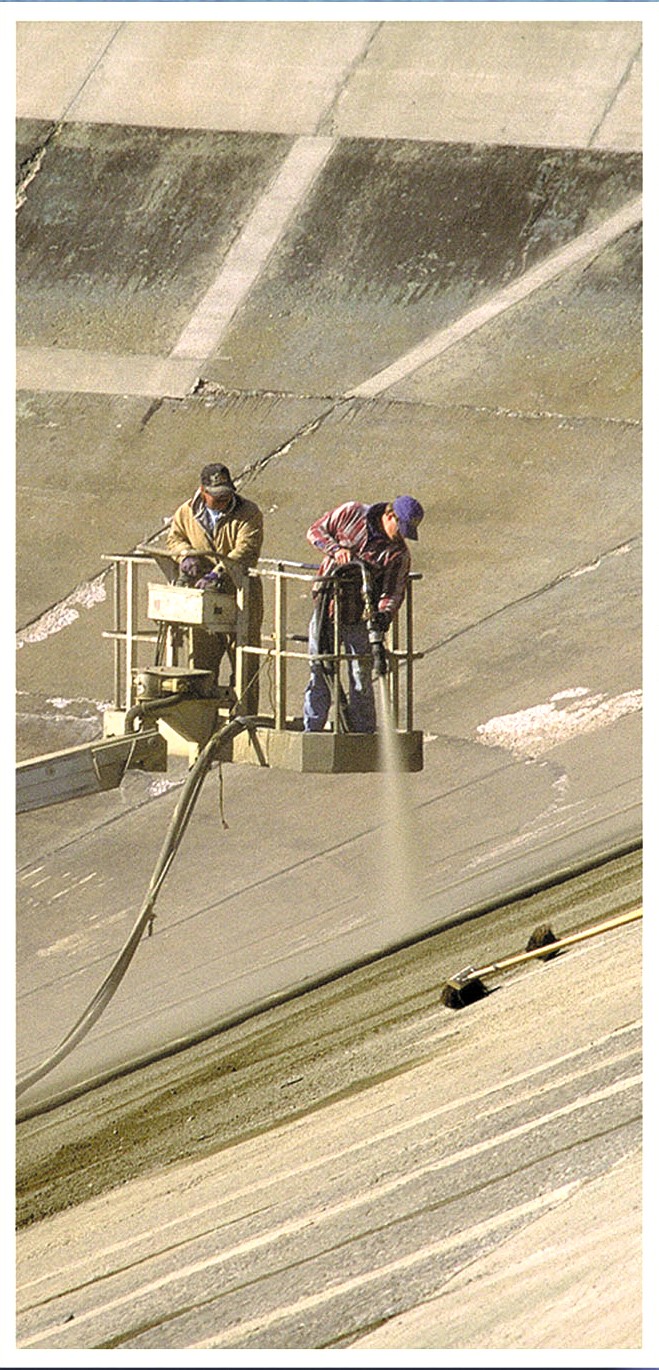

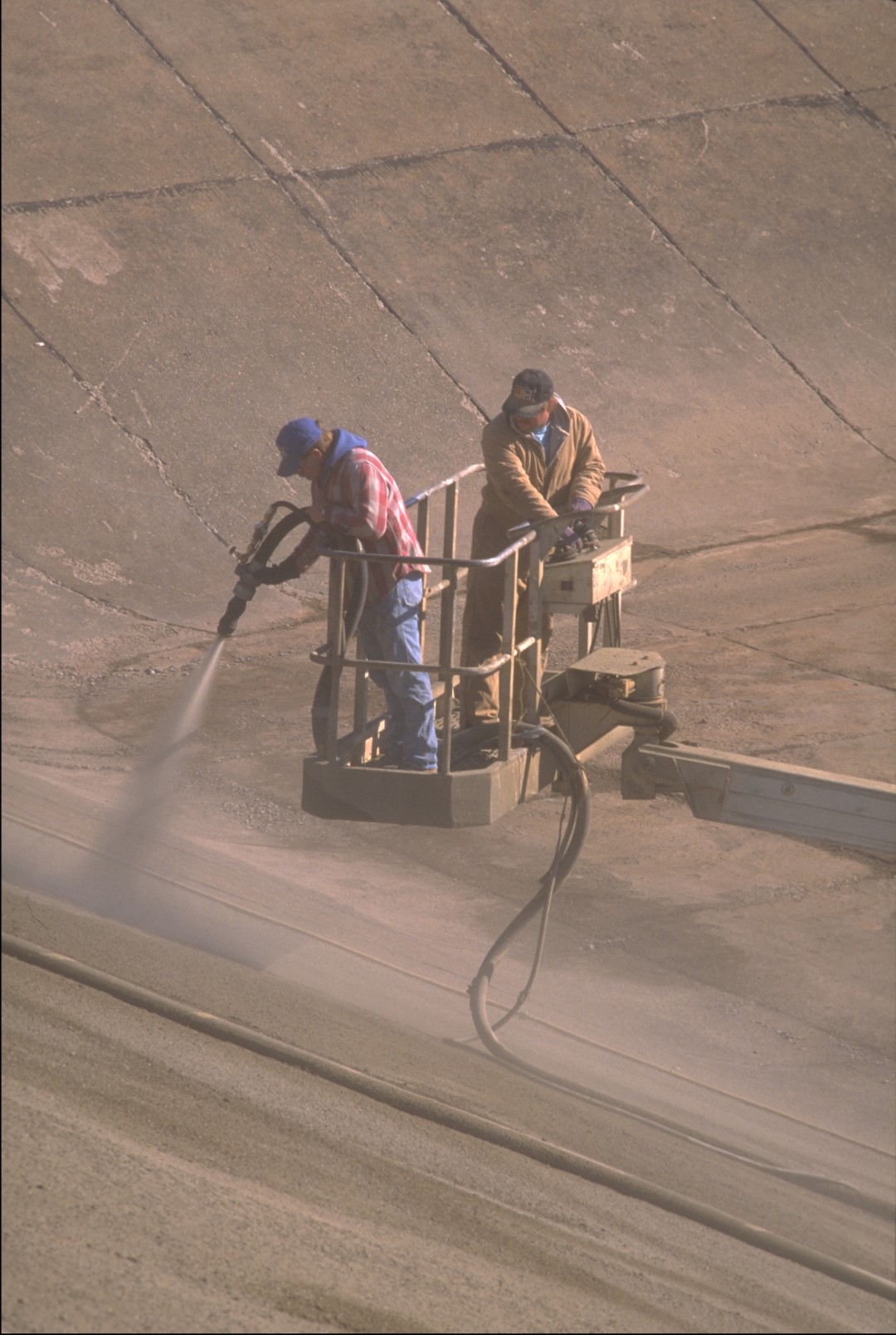

Originally constructed in the early 1900s, the Reservoir holds nearly 130-million gallons of water. The Reservoir’s basin was built with a challenging 30° pitch. According to Graciano Project Manager, Dave Sinclair, “The most difficult part of the restoration project wasn’t the steep slope of the Reservoir, it was the timeframe. The Reservoir concrete had to be repaired, resurfaced and ready for the liner in just three weeks.”

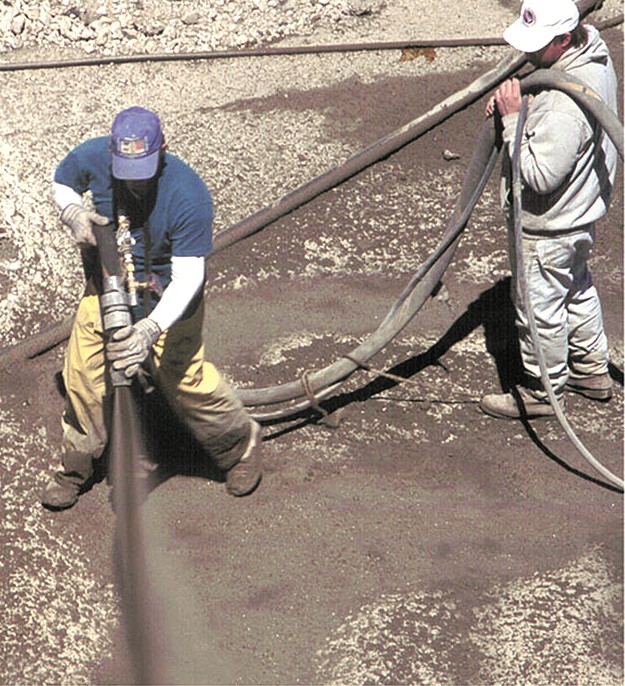

Graciano’s Restoration Team made repairs to surface cracks and spalls using the high-pressure pneumatic application of wet mix mortar (100-90 PSI) shotcrete—the economical alternative to poured-in-place concrete for curved structures.

Chester Engineers, construction managers to the Pittsburgh Water and Sewer Authority, specified shotcrete application as the repair method for the Reservoir. The US Army Corps of Engineers, City Engineers, Municipalities, Port Authorities and Dam Operators routinely specify shotcrete across the country for concrete rehabilitation projects—particularly for structures with constant exposure to water.

Testimonial

Dave Sinclair explained, “Low-cost and high-strength shotcrete can be adapted to meet the demands of virtually every rehab project in which concrete is used. Graciano’s technicians are highly skilled in nozzle operation and control. Shotcrete’s physical placement/installation is more rapid than traditional methods, further reducing the overall labor cost. It also reduces structure downtime and all of the associated interruptions.”

Project Details

Downloads

Project Included

- Wet & Dry Shotcrete

- Water Control Injections

- Pressure Washing

- Partial Depth Concrete Repair

- Full Depth Concrete Repair

- Expoxy Injection

Glossary Terms